Last Updated on June 20, 2024 by Michelle

While you can collect sap in a bucket to make syrup, if you have a few dozen trees, there is a much easier way. Today I’m going to break down for you exactly how we collect sap using a few different pumps. Not only does this system make our lives easier, it also allows us to make more syrup.

Now that you gotta love.

What if you just have a few trees?

I’m Michelle, author of Sweet Maple, Backyard Sugarmaking from Tap to Table (go here for a peek inside) and I’m elated that you found this page.

If you are a backyard sugarmaker with two or three trees to tap, you want to grab my book… it’s pretty much the Bible of Backyard Maple. But this post isn’t going to benefit you.

This article is for someone who has many trees to tap, who would rather not carry each bucket, one by one, from each tree back to their processing location. That’s exactly what we did for the first two years.

The first year, with a dozen trees, wasn’t so bad.

The second year, with twice as many trees, got exhausting.

This post contains affiliate links. See my full disclosure here.

Our turkey fryer pot and propane burner has served us well, and is truly all a backyard sugarmaker needs if they’re just tapping a dozen trees or less.

btw, if you want to upgrade or expand on a turkey fryer, this pot is a sweet upgrade with a spout and an extra thermometer that makes your job a lot easier. And this dual burner is great with stainless steel pans like this if your backyard operation grows, as ours did.

We still, for one more season at least, use 3 propane burners and a combination of pots and pans to boil down our sap that we collect from more than 100 taps. But we weren’t about to carry 50-100 buckets from the woods every evening, for the 6 weeks of sugar season. Many of you have asked me how we built our collection system, so this article will break it down for you.

When you have more trees to tap…

By our third winter of sugarmaking Bill decided to not double our previous year’s number of taps, but quadruple them. With more than 100 taps, buckets would not be an option. So we added lines, collecting sap into collection tanks.

Grab a copy of Sweet Maple for lots of insight into that big step, if installing collection tubing like this is something you’re considering.

But just installing lines to collect your sap isn’t enough. For two reasons:

- First, you’ll want a vacuum pressure on your lines, to create the highest quantity of sap you can in your short 4-6-week window of sugarmaking every year.

- Then, you’ll need a way to pump the sap out of your collection tanks and into your tank on your truck or gator that you’re using to transport the sap.

Keep reading for links to everything we use to make this all run smoothly (and make us lots of smooth-tasting maple syrup).

What you’ll need to make a similar set up…

The transfer pump

The heart of this whole collection operation is the transfer pump. This one works great for us, and of course we have lots of extra batteries.

On a side note, this happens to be no effort for us at all because Bill is a huge fan of Milwaukee. We have bright red Milwaukee drills, and awesome beacons of light (aka this LED stand work light that comes in handy if we’re working in the sugarbush at night). The same interchangeable, rechargeable batteries work for all of the above.

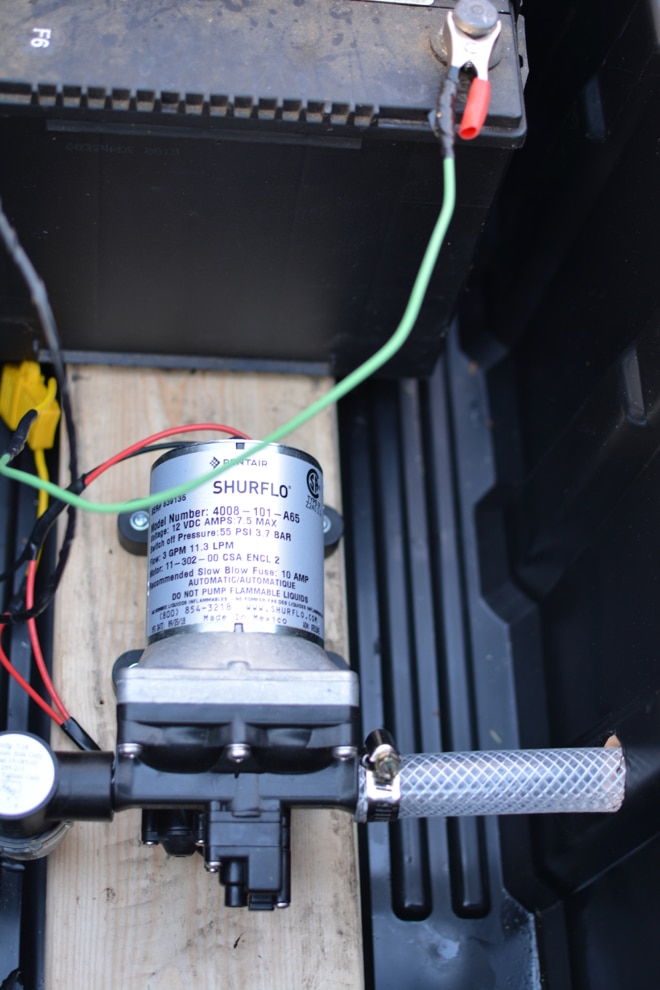

The vacuum pump

Then you’ll need a stationary pump that serves as your vacuum on your lines. We use this pump for that purpose and store it in a heavy-duty plastic tote like this in the woods, at the base of our network of collection lines. The sap is pulled into a collection tank where we then pump out the sap daily into another collection tank on the back of our gator. We connect the pump to the collection lines as well as into the large collection tank using this 3/4″ high pressure tubing.

The tubing

And we use a 1/2″ piece of copper from Home Depot or Lowes, connected to this type of tubing with a 1/2-inch shark bite fitting to pull the sap out of our large collection tanks or 20-gallon tubs. (We found our collection tubs at Tractor Supply; they’re made to serve as food bins for farm animals.)

Once the sap is transferred to the gator, it’s super easy to drive back to our processing area, where we will RO the sap and boil it down. We just attach a piece of tubing, open the spigot of our carrying tank, and let it flow.

btw, if you don’t know what I’m talking about when I say we RO the sap, this article right here, all about reverse osmosis for sugarmakers, will change you life and save you hundreds of dollars a year.

How we made our vacuum system…

Here’s everything we used to make this set up work for us:

Here are some other links that might interest you:

Professional Sugarmaker’s Tips on How to Make Maple Syrup

6 Ways Sugarmakers can Outsmart Squirrels

Check out this list I’ve put together, after many years of research, of 31 trees that can be used for sugarmaking

How to build your own Reverse Osmosis filter–step by step–and why you should

Taste and see that the Lord is good. Psalm 34:8

Pin this for later!

Click on the image below to pin this post.

Find out why SoulyRested was considered to be one of the Top 20 Must-Read Homesteading Blogs of 2018 and then one of the Top Homesteading Blogs of 2019 as well.

I’d love to connect!

To find me in some other neck of the woods, just click any (or every!) icon below:

And please follow along!

Hello,

After reading your book “Sweet Maple” I have a few questions:

1. I have ordered the parts to build the RO you use (thank you for the idea and how-to info). On page 68 of your book you state that after the RO process the sap must be processed soon, that it can’t sit “too long”. How long is “too long”? And if kept cold (low 30’s), will it be safe to delay evaporation longer? How long?

2. On pg 214, “Resources”, your web site is listed to find instructions on how to build Bill’s tubing reel (pg 45), and your DIY filter press (pg 97. I have looked through more than once, but am unable to find either of these. I would greatly appreciate your help finding these instructions.

3. I live on the Olympic Peninsula in northwest Washington. I have big leaf maple on my property and want to learn more about working with this species of maple. You include Pamela Williams (pg 136), from Vancouver Island, CA, who has specific experience with this tree. If at all possible I would greatly appreciate your sending her my email address in hopes she and I can correspond, share sap/ syrup information specific to our trees.

4. Though not mentioned in your book I would like your thoughts on check valve spikes.

I plan on trying 3/16″ tubing, using the slope of my property to create a vacuum. I saw a reference while researching suggesting that these spiles would prevent back flow of sap into the tree , and see they are listed in the Bascom catalog.

Thank you for all the help you have shared on your web site, and in your book. I am looking forward to a great sap/ syrup winter, but must end this correspondence as I hear my wife calling that it is time to have a piece of Oatmeal Chocolate Chip Skillet Cake!

Hi Rand,…

1. I recommend not waiting at all. If possible to plan accordingly you should always be processing your RO’d sap immediately. It’s just so discouraging to leave it overnight and find it smelling sour in the morning because it’s started to go bad.

2. Sorry, we had every hope of having those resources available but haven’t been able to pull them together.

3. Please join my fb group “Maple Syrup Awesomeness” that’s the best way to connect with Pamela as well as others in there who are experts at tapping Big Leaf.

4. I’m sorry I’ve never tried this, but again, I’m certain there are folks in my facebook group who could give you some feedback on this.

How do you know how much sap/water the tree can give up if you’re pumping it? It seems like you’re extracting the water instead of allowing the tree to give up what it can.

Great question. The Univ of Vermont’s Proctor Maple Center has done extensive research on this and assure sugarmakers that it actually does no harm to the trees. No one cares MORE about the health of the trees than the sugarmakers, for sure.