Last Updated on June 20, 2024 by Michelle

Want to know how to build your own Reverse Osmosis for making maple syrup?

Want to save money making maple syrup?

Every detail you need to know is all broken down for you right here.

I’m elated that you found this page. If you’re a backyard sugarmaker looking to save money, this article will make your day, just like it did for Jeff Whitmore and Eric Shufelt:

Hi, I’m Michelle. A backyard sugarmaker in New England, and author of Sweet Maple.

Please consider helping me support sugarmaking education worldwide with every purchase of SoulyRested Swag. You’ll find the latest designs right here (like the one I’m wearing here) .

But first, let me applaud you. Seriously. I have huge respect for DIYers like you who know what they want and can seriously build it.

I’m not like you. I love making syrup, and baking with syrup, making maple cream (my favorite form of maple), and writing about maple syrup, but I do not know how to build something like this awesome Reverse Osmosis set up that we have.

Nope, that’s all my husband’s ingenuity. And I have huge respect for Bill and for YOU, since you’re here.

Me? I wouldn’t know how to even cut the plywood the size I wanted it. True story.

Can you save money making maple syrup?

The best way to save money making maple syrup is to cut down your boil time, and save in your fuel costs. The best way to do this and save money making maple syrup? By building a Reverse Osmosis system for maple syrup. And that, my friend, is exactly what this article is all about.

Yep, you’ve stumbled across the Holy Grail for saving money while making maple syrup…

What is Reverse Osmosis for maple syrup?

A Reverse Osmosis system (lovingly referred to as “RO” in the sugar making world) is the same idea as that fancy filter many folks have under their sink, filtering their water.

But a sugar maker reverses the system, and instead of filtering out impurities to produce pure water, we filter out the water and keep the “impurities,” aka SUGAR. By removing a nice percentage of the water in the tree sap, we increase the brix of the sap and reduce our boiling time.

Read more about measuring brix in your sap and syrup here.

Save money and build a DIY Reverse Osmosis system.

So I asked Bill to walk me through exactly what he did to make this sweet contraption. Since it saves us hundreds of dollars every year in fuel costs as we boil our sap, I totally want to tell y’all exactly how to build your own.

I also list, below, every single item Bill bought to build our system.

If you are still learning how to collect, boil, and bottle maple syrup, head over here to this article about making syrup, step-by-step or, better yet, pick up a copy of Sweet Maple. It’s being hailed at the “Book of Knowledge of all Things Maple.”

But maybe you stumbled here wondering what an “ro system” is, I’ll explain…

What is a homemade reverse osmosis (RO) system?

A DIY Reverse Osmosis is exactly like a water filtering system. You know the ones that that filter out the impurities and leave you with wonderfully pure drinking water? (In fact, you’ll see below that’s exactly what we’re using–filters from a water purifying system.)

Except sugarmakers use the idea in reverse. We filter out the “impurities” (aka the sugars in the sap) and keep them. That’s what we boil down to make syrup. But after the sap has run through the ro system, we can spend a lot less time, energy, and fuel to boil it. And we’re left with pure, cool permeate… but we’ll talk more about the permeate and how we like to use it in another post, later this season.

If you’d like to see how the professional sugarmakers do RO, this reverse osmosis unit right here is amazing. (And here’s a facebook live video showing how it works.) Maybe some day we will upgrade to that fancy-shamancy gorgeous thing. But for now, our little homemade one gets the job done.

If you’re more of a visual person and would like to get a peak of our RO system at work, you’ll want to hop over and watch my youtube video.

Does Reverse Osmosis remove sugar from your sap?

No, reverse osmosis doesn’t remove sugar from your sap. In fact, the reason we want to run sap through an RO is the exact opposite. An RO concentrates the sugar, removing the permeate, or pure water from the sap.

By concentrating the sugar in the maple sap, a sugarmaker can save as much as 90% in fuel since he or she will have to boil the sap for a much shorter time. Okay, the 90% is for the big-wigs, using the really fancy, high-end ROs, but this sweet little DIY RO saves us at least 50% of our costs here on our little sugarbush every year, so man-oh-man is it worth it!

Can you run sap through RO twice?

Yes! Not only can you run your sap through your RO twice, but I highly recommend it!

You’ll save yourself that much more on fuel costs to boil down your sap, since you will have doubled the amount of water you’ve removed, but you also may notice a slightly more caramelized taste to your syrup. That’s a win-win in my book.

Does a DIY RO system really save money?

Our family lives on 14 wooded acres, and we cut and store a lot of wood. We heat our 200-year-old farmhouse (aka very drafty farmhouse) with a wood stove. All winter. All very-long-cold-New-England winter. There just aren’t enough hours in the day or trees in the woods to do it all. So we persoanlly choose to boil our sap with propane.

But whether you’re a backyard sugarmaker who uses propane or wood for fuel, a homemade ro system will save you a boatload of time and money. (Read about Ray Ingham’s ro experiences below.)

Afterall, we all wanna save on fuel, no matter where were get it, can I get an “amen”?

Of course, no matter what you use for fuel, cuddling with a barn cat while you watch the sap boil makes everything a little more puuurfect. (Sorry, bad pun.)

If you wanna read more about why we RO, go here. Wanna know how we even do some natural RO for FREE? Read this article right here. Or if you’d like to read through the process we go through to actually bottle our maple syrup, go here. Otherwise, read on…

Is it hard to build a DIY Reverse Osmosis system?

Here’s our Reverse Osmosis set up. It’s rather simple, it’s rather small, but it’s totally huge on savings.

How long does it take to build your own Reverse Osmosis (RO) system? Honestly, getting all the pieces is the largest drain on your time. Once you have all the parts in front of you, it’ll take you a few hours, tops. Well, that is if you’re like Bill. If you’re like me. . . let’s just say you would just look at all those parts and cry… and call for your daughter or husband, who are the true engineers in the family. . . then go bake some maple cookies while they do the hard work. (If you need a giant cookie fix–and I do mean giant–you’ll want this recipe.)

How long does it take for a 5-gallon bucket of sap to go through the system? We use filters intended for 150 gallons per day, and 5 gallons goes through in about 45 minutes.

At what pressure do we run our RO? We run it at 60-70 psi, which we regulate with the needle valve.

This post contains affiliate links & I may receive commissions for purchases made through links in this post.

Go here to read the full (ultra fun) legal disclosure about that.

To build a reverse osmosis set up of your own–and seriously slash your fuel costs–you’ll need a piece of plywood, or something similar, for mounting everything, and you’ll need the following items, which are all pictured below as well, in the order they’re listed. Click either the item name or the picture for ordering information.

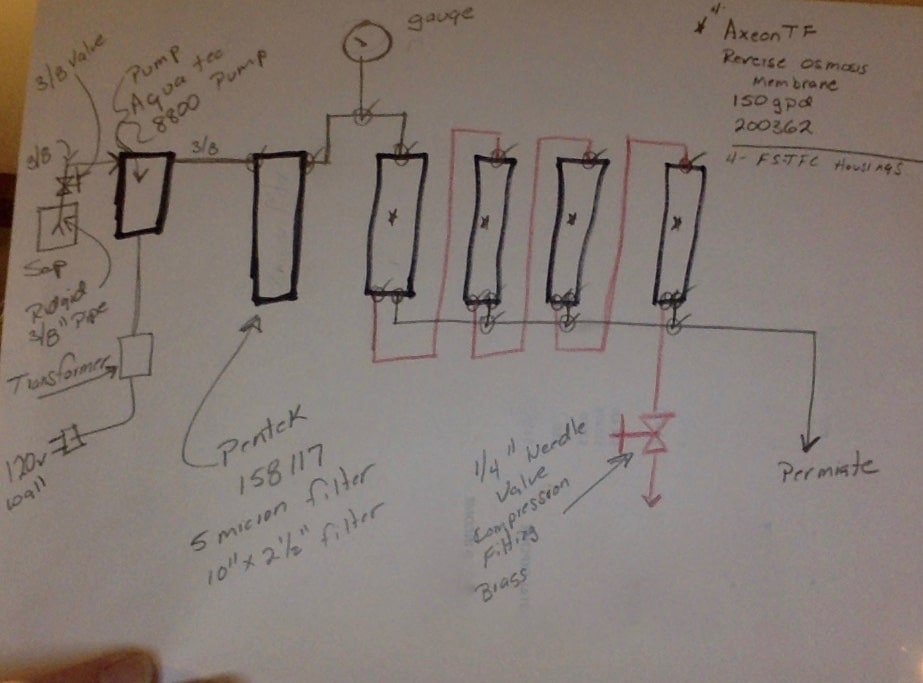

Then keep scrolling for a totally unprofessional, hope-you-understand-what-he’s-talking-about drawing of Bill’s design.

The items we used for our DIY Reverse Osmosis for making syrup

Pump and transformer, membranes* (you will need 4 but see other links for varying gallons per day), membrane casings (4), filter 4-pack, filter housing, pressure gauge, a straight needle valve.

* For your membrane, you can choose the one linked above, for 50 gallons per day, or upgrade to one for 100 gpd or 150 gpd. (We use the 150 gpd filters. We have 110 taps and process roughly 5 gallons of sap through the RO every 45 minutes.)

btw, if you don’t already have Amazon Prime, I highly recommend it. We live in nowhere-ville, so traveling to Lowes is quite a trek. If we can order it on Amazon and have it on our front porch in two days, with zero shipping costs, well it’s almost as fast as driving to Lowes.

But seriously, you can try out Prime for totally free for 30 days. If nothing else, sign up and get all these goodies delivered to your door for free shipping, right away, so you can start saving money on your propane.

Try Amazon Prime 30-Day Free Trial by clicking through this link.

You’ll also need some tubing and connectors, as well as another valve. These items, which I couldn’t find on Amazon, I list below, along with where I did find them and the item #s or purchasing info you’ll need.

The items we picked up at Lowes for our DIY Reverse Osmosis system

1/4″ T (you’ll need 4 of them) Sharkbite item # 835039, model #25427Z

1/4″ male x 1/4″ quick connect 90° (you’ll need 5 of them) Sharkbite item #83500, model #25433

1/4″ male x 1/4″ quick connect straight (you’ll need 8 of these) Sharkbite item #835025, model #25413Z

3/8″ x 1/4″ male quick connect (just 1) Sharkbite item #835028, model #25416Z

3/8 polyethylene tubing (25′ of it) item #879277, model #98634

1/4 polyethylene tubing (25′ of it) item #814305, model #98584

3/8″ quick connect ball valve (just 1) Sharkbite item #835049, model #25438Z

ridgid 3/8″ x 30″ pex tube (30″ faucet) item #751655, model #7227-30-38-2

Here’s the artwork I promised you.*

*NOTE: the red lines in Bill’s drawing represent clear tubing connecting the filters in sequence above. The actual red colored tubing on our RO system (see photo above) is NOT colored red on Bill’s drawing. Sorry if that is confusing. Bill confuses me sometimes too. 🙂

How much water does reverse osmosis take out of maple sap?

In the end, a DIY Reverse Osmosis system will take a lot of the water out of your syrup. We typically run our sap through a few times and get our sugar concentration up to about 8% (vs. the 2% we start with). We’ll take 100 gallons of sap down to about 40 gallons of sap before we start to boil it into syrup.

If you want to know more about choosing a refractometer that will help you measure your sugar levels of your sap so you know how much more concentrated your RO system is making your sap, read & watch the video here about How to Make Syrup–what tools do you need?

Is Reverse Osmosis worth it for maple syrup?

Yes, the afternoon or two that it will take you to build a DIY Reverse Osmosis system, and the money you invest into the parts will absolutely pay you back in the long run. Depending on how many trees you tap, it will most likely pay for itself in just a few years.

Read a few reviews of this system below to see the return on investment others are reporting. It really is a great investment that pays off quickly.

What are people saying about this DIY RO system?

Mark & Colleen Falardeau, backyard sugarmakers who built this RO system, explain,

“It cost us roughly $300 to make our RO and it takes sap from 2-3% sugar content to 7-8% in one pass! We have 100 taps and the wood saved and time saved in one season has made it worth every penny!!“

Chris M. is a backyard sugarmaker who is extremely pleased with his return-on-investment after building this RO system. He wound up making twice as much syrup using almost half the amount of propane:

“I made 2 gallons of syrup this year, using 2.5 tanks of propane. How does that compare to my costs last year? Last year, I made about 1 gallon of sap and used 4(!!!) tanks of propane. That is insane return on my investment!“

Ray Ingham is a hobby sugarmaker in Huntington, Vermont. Ray says,

“For anyone who is thinking about building one of these, I say do it! I put one together last year using 4 100 gpd membranes. It cost me about $350 and was well worth it. I’m retired and a one-man band. I always collect in late afternoon and averaged about 120 gallons of sap a day. I would run the RO over night and extract about 7 gals. of pure water an hour. By morning I would have 30 – 40 gallons of sap to boil down. My sap went from 1.5% sugar to 4 to 5% sugar after running through my ro. I would boil this down in less than 3 hours in my 2×4 pan. I saved a incredible amount of time and firewood.”

Heather Gilson, whose family has about 50 taps in their backyard on any given year, explains,

“My husband built one last year and man was it a time saver for us!! We saved so much time in not splitting a bunch of extra wood, not having to boil for extended periods of time. It was amazing!”

How do you clean RO membrane for maple sap?

You’ll be surprized at how easy it is to clean your RO membranes and use them for many seasons.

To clean the membranes after each use: Simply run your permeate (the water that your system pulls out of your sap) through your system at the end of your day. That will be all the membranes need to be clean and ready to use the next day.

To clean the membranes at the end of the season: Simply remove your membranes and wash them under running water thoroughly. Place them in a ziploc bag and store them in the back corner recesses of your refrigerator until the next sugar season.

More syrup-related information:

How to use pumps to make your sap collection so much easier

My detailed list of all the best tools for a backyard sugarmaker

Make some amazing Maple Cream with your syrup

You can also follow my Maple Syrup pinterest board right here. Everything I ever write about maple gets added to that one board.

Taste and see that the Lord is good. Psalm 34:8

Pin this for later!

Click on the image below to pin this post.

Find out why SoulyRested was considered to be one of the One of the Top Homesteading Blogs.

Glance at my Resource Page if you’d like to get a glimpse of all the supplies I use and recommend for everything from gardening, to homeschooling, to chicken care, to nature journaling, to maple syrup making.

I’d love to connect!

To find me in some other neck of the woods, just click any (or every!) icon below:

I purchased one yesterday and it is to arrive today. Can’t wait to try it out

Michelle, My first time finding your web page and read thru all of your posts. I am building an RO fashioned after one of my neighbors here in WI. and it is exactly like your Hubby’s setup. Some of them are in “series” like your’s and some RO’s are set up in “parallel”. It seems they both work well, just the way they are plumbed.

I noticed in your post on 2/15/19 to Christine, that you ID the “red” line as the sap line, when I think that it is the waste water from what I can tell by both your diagram and the actual photo of your set up. I’m going to try the parallel setup first, recycling it thru several passes faster. (Easier to tell if one of the membranes is plugged as each has a separate discharge line that you can monitor). The drawback is that you need 4 needle valves, one for each sap line/canister to create the proper back pressure. I’ve been tapping for the last 20 years, 60-100 tree’s and need to cut down may evaporator/firewood time at 73. Thanks for doing this, we will follow up with some of your cookbooks, etc.

Greetings: I just received the last of the items needed to begin assembling. My only question at this time is how do you do a backwash to clean the filters? I am sure that this will only be first of many questions. Thank you in advance for your time as well as your assistance.

Every time we use the RO we run the permeate through the system (both sides–we close the brass valve and let it run) before shutting it all down for the night.

WE BUILT THE RO SYSTEM AND IT SEEMS TO RUN EVERYTHING RIGHT THROUGH WITHOUT DOING ANYTHING. WHAT IS THE PURPOSE OF THE NEEDLE VALVE ON THE LINE. I DO NOT HAVE THAT ON THERE. IS THAT MY PROBLEM? WHAT PRESSURE SHOULD I HAVE? THANKS AGAIN.

Yes. You do need the needle valve. It traps all the the sap in the filter doesn’t let it through.

It appears that the RO filters will be a challenge to change due to the lines set top and bottom on the casing will not allow the top of the casing to be unscrewed???? I’m building one but now I see the challenge with the first filter change. That top will not spin unless the line is cut. Is this not correct?

Great question, Jerry. But no, Bill made the unit intending to take the filters out at the end of each season to clean and store and reuse the next season. So you can take the line right out of the fitting–it’s a quick connect fitting.

About quick connects:

Cut the tubing pretty square. I use pruning shears.

After 3 disconnections, the tubing may be scarred and leak.

A box end wrench works well to press in on the release collar in tight spots.

I keep having to relearn to push the tubing ALL THE WAY IN.